Manufacturers – Improve Productivity With Software Solutions

The manufacturing industries around the world are constantly looking for ways to become more efficient, and driving down costs without compromising quality or output are always at the forefront of any company’s goals. Modern software solutions are designed to analyse the manufacturing process, and with a range of impressive tools, it is possible to make a difference.

Computerised Maintenance Management Systems (CMMS)

One of the leaders in this industry can be found at http://www.idhammarsystems.com/, a dynamic, forward thinking company that is dedicated to producing software to help manufacturers improve efficiency in a number of areas. Their Windows based software is easy to use, and with a range of powerful analytical tools, it is possible to identify areas for improvement, and either improve production or reduce running costs.

What CMMS can do for your Business

The many benefits of CMMS include the following:

- Effectively manage day to day running costs and eliminate unnecessary expenditure.

- Dramatically improve performance by reducing production line downtime.

- Spread the maintenance workload and improve employee performance.

- Reduce risks by using powerful analytical tools.

It is possible to create an unlimited hierarchy permissions framework, which only allows authorised users to access the system, which is ideal for comprehensive asset management.

Instant Communication

Essential maintenance tasks can be completed without the need for lots of documentation, as each engineer can receive their work schedule via their email or even smartphone, which eliminates the need for endless reams of paperwork, which in itself brings a saving.

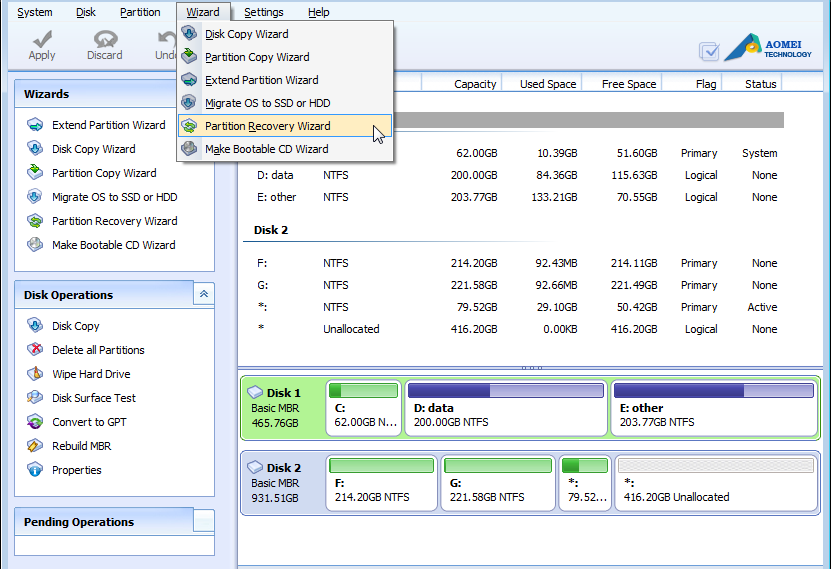

Analytical Tools

The “What if” tool enables a software engineer to hypothesize, and by running the program, it is possible to minimize risks before actual implementation. This tool is invaluable when a business is looking for ways to improve production or reduce costs, as it allows the engineer to see the results of a change before it is actually implemented. Analysis is the key to understanding the manufacturing process and how it can be improved, and with so many powerful tools, your business will benefit in more ways than one.

Customised Solutions

The software developer is able to customize the software to suit the client’s needs. You might have a single production facility and it operates independently, or you might have a series of manufacturing plants in various locations, and the software can be designed for either scenario. Essential maintenance tasks have to be carried out, and if this can be completed with the minimum of production line downtime, everyone is happy. The communication between engineers can also be made more efficient by automated reminders to relevant staff about maintenance issues, and if the line stops for any reason, the right people will instantly be informed.