The Importance Of Board Level Shielding For Computer Systems

Be it dispensing cash through ATMs, monitoring vital health signs via tiny devices, facilitating multi-channel communication or controlling air traffic in the world’s busiest terminals, it’s totally amazing to think just how many ways electronics and computer systems have transformed our lifestyle. At the core of this electronic revolution lies people’s ability to bring electrons under their command to run machines and process information. Electrons are the tiny particles within atoms that carry electrical energy. When they are directed around defined yet complex paths known as circuits, they become capable of processing signals, and storing and processing information. Thus it is not just the elements of an electronic device that matter; the defining element is the way these components are arranged in circuits. The more complex the circuit of an equipment, the more intricate jobs it can perform. No wonder, computers have dense and complex circuit boards comprising millions of separate pathways. Just like any other electronic devices, computers, too, give off electromagnetic emissions. This can never be stopped, but if left unattended it can damage the circuits or the brain of a computer beyond repair. That’s why a computer’s circuits need to be designed in a manner so that it can minimize electromagnetic interference. However, sometimes even the best design cannot sufficiently block the effects of radiation. And that is when you need proper board level shielding, which can not only block the emissions from within the computer, but also help cut down the amount of radiation into the environment.

How Board Level Shielding Works

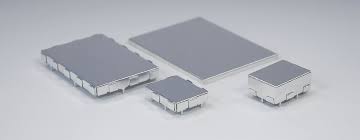

These days the shielding process for any device begins right at the design stage. Apart from equipping circuit boards with active and passive filters, manufacturers also incorporate effective shielding in printed circuit boards (PCB) – a circuit, which is printed chemically onto a plastic board. PCB shielding helps optimize PCB tracks and reduce the intensity of EMI signals. In most cases this is achieved by incorporating an enclosure that reflects the electromagnetic waves into the ground. This process is based on the Faraday Cage principle. According to this design theory, such an enclosure made of conductive materials results in a zero electrical field, helping suppress the effects of electromagnetic interference. Computer systems are becoming increasingly smaller and thus the challenge lies in designing shielding solutions that can enclose a dense circuit, without affecting its speed.

Selecting the Right Product

Computer manufacturers use different types of shielding solutions to keep their circuit boards protected from EMI radiation. Reputable EMI shielding providers offer customized solutions for board level shielding, which may vary from surface mounted enclosures and multi-cavity shields to many other innovative systems. They can be made of different metals including copper, brass, beryllium copper or stainless steel. Consider following points to choose the right shielding product:

- The amount and frequency of radiation

- The amount of reduction needed

- Location of the source of radiation

- How much space is available

- Weight of the computer

- Grounding options

When it comes to procuring board level shielding for a computer system, always go with a trusted name in the industry. It would be better to purchase it from a manufacturer who is capable of tailoring the product to your specific needs. If you are fine with out-of-the box products, select a manufacturer with a wide-ranging product line-up. If you are seeking customized solution, clarify your design concept and keep a tab throughout the manufacturing process. Always select a company that uses time-tested and standardized methods to manufacture EMI shielding solutions. Most importantly, make sure, the company you are considering provides excellent after sales support. Selecting the right EMI product will ultimately improve the quality and flexibility of the circuit board of your equipment.